FMEA (Failure Mode and Effects Analysis) is a powerful risk assessment tool, integral to Six Sigma methodologies, that identifies potential issues within products or processes before they cause disruptions. By systematically examining system components and prioritizing risks based on severity and likelihood, FMEA fosters data-driven decision-making, effective resource allocation, and proactive risk mitigation. This approach enhances product/service quality, reduces operational instability, and aligns with Six Sigma's core principle of defect reduction. Implement FMEA to build supply chain resilience, optimize resource allocation, and proactively address vulnerabilities in a complex global landscape.

In today’s complex global supply chains, assessing supplier risks is vital for maintaining operational resilience. This article explores the powerful FMEA (Failure Mode and Effects Analysis) methodology as a comprehensive risk assessment tool within the framework of Six Sigma. We’ll guide you through understanding FMEA, its application in supplier risk management, identifying potential failures, prioritizing risks using severity and occurrence ratings, and implementing FMEA for enhanced supply chain resilience. Discover how this structured approach ensures that every potential failure mode is addressed, minimizing disruptions and maximizing operational efficiency.

- Understanding FMEA: A Comprehensive Risk Assessment Tool

- The Six Sigma Approach to Supplier Risk Management

- Identifying and Categorizing Potential Failures

- Risk Prioritization: Assigning Severity and Occurrence Ratings

- Implementing FMEA for Effective Supply Chain Resilience

Understanding FMEA: A Comprehensive Risk Assessment Tool

FMEA, or Failure Mode and Effects Analysis, is a powerful risk assessment tool used to identify potential issues in a product or process before they occur. It’s a systematic method that helps businesses in various industries, particularly those adopting Six Sigma methodologies, to prioritize risks effectively. By thoroughly examining each component or step within a system, FMEA enables organizations to anticipate failures and their consequences, allowing for proactive measures to mitigate these risks.

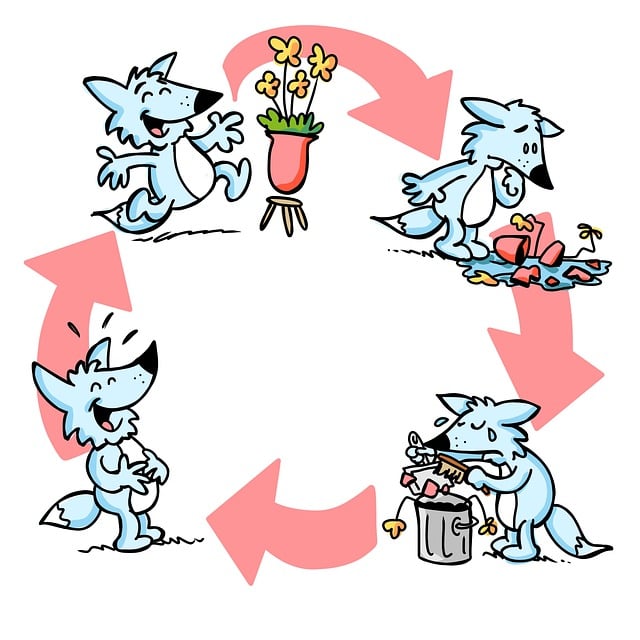

This methodology involves a structured approach where potential failure modes are identified, analyzed, and prioritized based on their severity and likelihood. It encourages teams to think critically about every aspect of a process, fostering collaboration and enhancing overall risk management. By using FMEA, companies can make informed decisions, allocate resources efficiently, and implement strategies that enhance product or service quality while minimizing potential disruptions.

The Six Sigma Approach to Supplier Risk Management

The Six Sigma Approach leverages data-driven methods, such as the Failure Mode and Effects Analysis (FMEA), to assess and mitigate supplier risks effectively. FMEA is a structured tool that identifies potential failure modes within a supplier’s processes and quantifies their severity and likelihood of occurrence. By systematically evaluating these factors, organizations can prioritize risks based on their potential impact on key performance indicators. This risk prioritization aligns with the core principles of Six Sigma, which focus on reducing defects and improving quality through process optimization.

Incorporating FMEA into supplier risk management enhances the precision and efficiency of decision-making. By analyzing failure modes, organizations can implement targeted corrective actions to strengthen their supply chain resilience. Moreover, the prioritization aspect ensures that resources are allocated to address the most critical risks first, optimizing both time and financial investments. This strategic approach not only reduces the likelihood of disruptions but also enhances overall operational stability and product quality in Six Sigma fashion.

Identifying and Categorizing Potential Failures

Identifying potential failures is a crucial step in the FMEA (Failure Mode and Effects Analysis) process, which serves as a powerful tool for risk prioritization within Six Sigma methodologies. This systematic approach involves meticulously examining every aspect of a product or service to uncover possible failure modes and their underlying causes. Each identified failure mode is then categorized based on its severity, likelihood, and potential impact on the overall system or process.

By applying FMEA, organizations can prioritize risks effectively. This categorization allows for a structured evaluation of different failure scenarios, enabling decision-makers to focus on the most critical issues first. It also facilitates the implementation of targeted mitigation strategies, ensuring that resources are allocated efficiently to address high-priority risks. This organized approach to risk management is particularly valuable in complex manufacturing or service industries where numerous variables can contribute to potential failures.

Risk Prioritization: Assigning Severity and Occurrence Ratings

In the context of FMEA (Failure Mode and Effects Analysis) and Risk Prioritization in Six Sigma, assigning severity and occurrence ratings is a critical step that helps to focus resources on the most pressing issues. Each failure mode is evaluated based on its potential impact or severity, typically rated on a scale from 1 to 10, where higher numbers indicate more severe consequences. This involves considering factors like product safety, production delays, financial losses, and customer satisfaction. Additionally, occurrence ratings are assigned to determine the likelihood of a failure happening, ranging from low to high, reflecting the frequency or ease with which it can occur.

By combining severity and occurrence ratings, risks are prioritized. High-severity, high-occurrence issues should be addressed first as they represent significant threats. This structured approach ensures that Six Sigma projects allocate time and efforts effectively, targeting areas where improvements will have the most substantial impact. FMEA facilitates this process by providing a systematic framework for identifying, analyzing, and managing supplier risks, ultimately contributing to enhanced product quality and process reliability.

Implementing FMEA for Effective Supply Chain Resilience

Implementing FMEA for Effective Supply Chain Resilience involves a systematic approach to identify, analyze, and mitigate potential risks that could disrupt your supply chain. This methodology, rooted in Six Sigma principles, prioritizes risks based on their severity, occurrence, and detectability – a process known as risk prioritization. By applying FMEA, organizations can proactively address vulnerabilities and strengthen their supply chain resilience.

It enables them to make data-driven decisions by quantifying the potential impact of each risk, ensuring resources are allocated efficiently. This proactive stance contrasts with reactive measures, allowing businesses to not only respond to crises but also anticipate and prevent them. Ultimately, FMEA equips companies with a robust framework to navigate an increasingly complex and uncertain global landscape, fostering supply chain agility and sustainability.

Assessing supplier risks using the FMEA (Failure Modes and Effects Analysis) methodology, coupled with the Six Sigma approach, is a powerful strategy for enhancing supply chain resilience. By systematically identifying, categorizing, and prioritizing potential failures, organizations can effectively mitigate risks and ensure business continuity. This structured process allows for data-driven decisions, enabling companies to assign severity and occurrence ratings that guide strategic planning. Implement FMEA for enhanced risk prioritization within Six Sigma, and gain a competitive edge through improved supplier risk management.